| Ceramic Filters |

Skyline Components, LLC

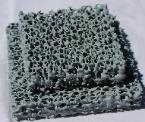

Ceramic Foam Filter

Ceramic foam filters have a foam-like porous structure. They are

made of refractory materials that are resistant to molten metal

erosion. They are mainly used in the field of metallurgy and

casting metal liquid filtration and purification to remove

undesirable nonmetallic inclusions and reduce trapped gas that

are contained in the casting. There are three ceramic foam

filters, alumina, silicon carbide (SiC) and zirconia foam filters.

They can be supplied in round, square, rectangular or other

customized shapes with different pore sizes and porosities.

Extruded Ceramic Filter

Extruded ceramic filter has straight channels in honeycomb

structure. It is mainly used in metallurgy and foundry industry to

filter out impurities, reduce casting porosity, eliminate turbulence

in the metal stream and improve casting quality.

Characteristics

o Light weight

o Large surface area through-hole rate

o high pass rate

o Good chemical stability and corrosion resistance

o High mechanical strength

o High thermal shock resistance

Specifications

Ceramic foam filters have a foam-like porous structure. They are

made of refractory materials that are resistant to molten metal

erosion. They are mainly used in the field of metallurgy and

casting metal liquid filtration and purification to remove

undesirable nonmetallic inclusions and reduce trapped gas that

are contained in the casting. There are three ceramic foam

filters, alumina, silicon carbide (SiC) and zirconia foam filters.

They can be supplied in round, square, rectangular or other

customized shapes with different pore sizes and porosities.

Extruded Ceramic Filter

Extruded ceramic filter has straight channels in honeycomb

structure. It is mainly used in metallurgy and foundry industry to

filter out impurities, reduce casting porosity, eliminate turbulence

in the metal stream and improve casting quality.

Characteristics

o Light weight

o Large surface area through-hole rate

o high pass rate

o Good chemical stability and corrosion resistance

o High mechanical strength

o High thermal shock resistance

Specifications

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|